What is a Materials Recovery Facility (MRF)? That's a hard question for most people to answer. Even seasoned veterans of the waste and recycling industry may have a hard time answering it in detail. In this post, we cover everything you need to know about material recovery facilities, including why they exist, how they operate, the different kinds of MRFs, the inefficiencies associated with them, and how RoadRunner's approach to recycling eliminates the need for them altogether! Read on to learn more.

What Is A Materials recovery facility (Mrf)?

A materials recovery facility, or MRF (pronounced like 'murph'), receives, separates, and prepares recyclables to be sold to an end buyer. An MRF uses a combination of equipment, machines, and manual labor to separate and prepare the materials. There are two main types of materials recovery facilities used by traditional hauling companies, which are detailed below:

Dirty MRF

Dirty MRFs accept recyclable materials combined with municipal solid waste. To separate the recyclables from the waste, the facilities use a combination of manual and machine-based sorting. The recyclable materials then undergo processing to meet industry quality standards. According to Waste 360, a large dirty MRF can process more than 700 tons of materials per day. Although they are able to process very high volumes of materials, a large percentage of the processed materials, especially cardboard and paper, are not recyclable due to material contamination.

Clean MRF

Clean MRFs accept recyclable materials from residential and commercial businesses that are already separated from solid waste. In most cases, Clean MRFs process single-stream recyclables, which is the most common recycling method where all materials (paper, plastics, metals, glass, and cardboard) are collected together in one recycling dumpster. Single-stream materials get sorted by specification and then they are processed and prepared for the end buyer. Clean MRFs recycle more materials than dirty MRFs, but the final number of materials that end up being recycled is still low due to contamination issues that arise from 'commingling' the materials in one dumpster.

HOW DO MRFS OPERATE?

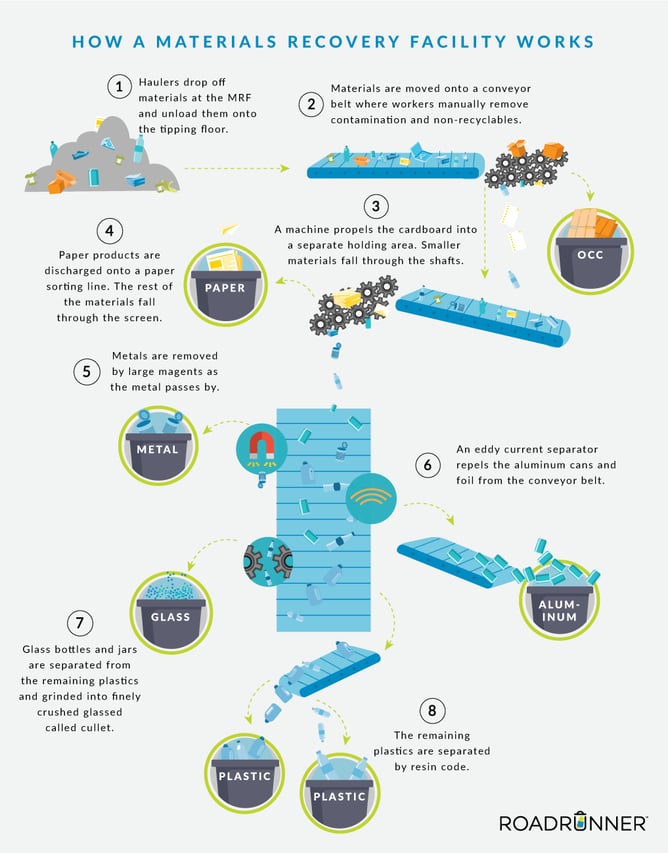

The sorting and processing methods are very involved. Here's an overview of what happens once materials arrive at the MRF:

The Dirt on MRFs

Processes ARE OUTDATED

To be recycled, materials must be clean, contamination-free, and valuable, but the MRF's inefficient and out-dated processes lead to low recovery rates. For example, unloading the materials onto the tipping floor causes large amounts of glass breakage and material contamination. When all of the solid waste and broken materials are mixed with the valuable recyclables, high amounts of contamination occurs. Unfortunately, the inefficiencies result in the majority of processed materials ending up in landfill.

Inefficient sorting METHODS

Machines and robots at the MRFs are not foolproof, so manual sorting is needed at MRFs to identify recyclables among the massive amount of non-recyclable or contaminated materials. Due to the complex nature involved with identifying certain recyclable materials, a considerable amount of items that can be recycled are lost in the process and end up in landfill.

HIGH CONTAMINATION RATES

Most traditional haulers employ single-stream recycling, the most common recycling method in which all materials are mixed, or commingled together, in one dumpster. The major issue involved with this method of recycling is contamination. Contamination is caused by a number of factors, including plastic bags, solid waste (trash), food and drink residue, and large objects. In the single-stream approach, less than half of the materials processed at a MRF are recovered for recycling due to high contamination - the rest are sent to landfill.

high OPERATING expenses

Material recovery facilities, by nature, are extremely expensive to build, operate and maintain. The costs associated with these 'assets' are typically passed on from the hauling company that owns the facility to their customers. With the understanding that this 'model' for recycling is out-dated and inefficient, the related-costs that are passed on to customers will continue to rise as expenses for updating and maintaining the facilities rise for the hauling companies. Below are some additional points to keep in mind about this:

1. Large, outdated sorting machinery and equipment are costly and require significant upkeep and maintenance.

2. Due to the high numbers of non-recyclable trash that enters MRFs, the equipment and machinery is constantly breaking and causing processing delays.

3. Safety is a huge concern for workers, which results in expensive labor and insurance costs.

4. The prices of gas, equipment, and labor have sky-rocketed in the past couple of years.

how Do the inefficiencies impact the customer?

![]()

LOW RECYCLING RATES

Due to contamination, inefficient sorting, and outdated processes, only a fraction of your business' potentially recyclable materials actually get recycled. It's estimated that 80% of recyclables that enter an MRF end up in landfills.

![]()

HIGH EXPENSES

A typical waste bill from your hauler is full of fees and charges designed to help the hauler cover the inefficiencies of the MRF - like equipment updates/maintenance and contaminated single-stream recycling. Again, these costs are passed on to the customers who end up paying more than they should for their recycling service(s).

RoadRUnner's process Eliminates The Need For materials recovery facilities altogether

RoadRunner eliminates the need for recovery facilities altogether by implementing a clean-stream recycling process for our customers. In the approach clean-stream to recycling, materials are sorted by stream (Cardboard, Commingled, Mixed Paper, and Compost) at our customer's facilities. We significantly increase recycling rates and lower costs by taking recyclable materials, that would have otherwise gone to an MRF, directly to a local buyer. So, while single-stream recycling may seem like a good approach for businesses to recycle, clean-stream recycling achieves higher recycling rates and increased savings!

By making recycling more efficient, we are able to reduce costs associated with waste and recycling; meaning your business spends less and recycles more with RoadRunner. Let us know your thoughts in the comment section below and send us a note if you're interested in recycling more today!