Sustainability is the mission. Positive cost-benefit is a requirement. Brand perception is a byproduct. But, at the heart of every “zero waste to landfill” commitment is one fundamental fact: sending waste to the landfill is something to be avoided.

As the largest legacy brands in the United States and around the world line up to announce responsible waste diversion and recycling goals, it’s important as a business to understand the undertaking.

By comprehending the concept of zero waste to landfill (ZWTL) and how to transform your business’s operations to meet the often-targeted sustainability goal, you’ll be able to divert from our nation’s economic and environmental collision course with a mountain of waste.

What Does Zero Waste to Landfill Mean?

For the full context, it’s helpful to start with America’s landfill crisis. In short, landfills are the third-largest source of human-caused methane emissions, they leak toxic leachate into our soil and water, and they’re filling up—seven states will be completely out of capacity in five years’ time.

So, the logical solution is to send less waste there, thus the rise of ZWTL.

The concept seems entirely straightforward, but the definition of zero waste to landfill has a few different versions. Making matters more complicated, the ideas of “zero waste” and “zero waste to landfill” are very different in execution.

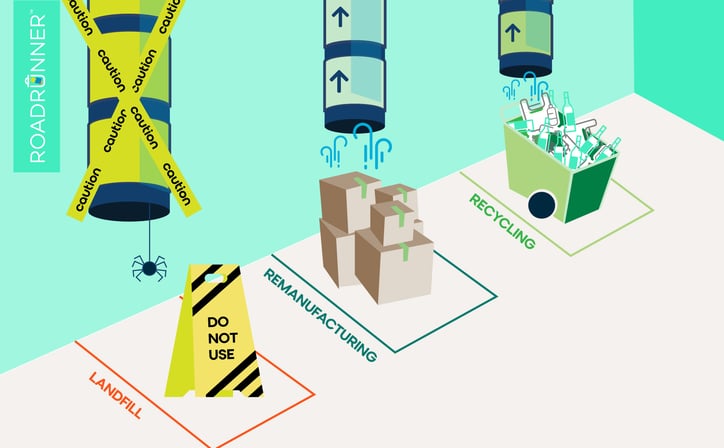

As a simple definition, zero waste to landfill is an overall waste reduction strategy with the ultimate goal to eliminate the volume of waste and material ending up in landfill. Encompassing the entire life cycle of an organization’s products or services, zero waste to landfill takes into consideration ethical, economical, environmental, and efficient decision making.

Broad in scope, the Zero Waste International Alliance (ZWIA) adds specificity to the collective definition, positing that a certified zero waste company achieves “at least a 90 percent resource recovery rate, which means there may still be a 10 percent stream of mixed materials, some of it being non-recyclable, non-compostable and non-reusable discards that will need to be disposed.”

Of the remaining 10%, the “residual,” it’s expected that the company will attempt to sort remaining recyclables or seek biostabilization through anaerobic digestion and bioenergy solutions before landfilling as a final resort.

That’s also where confusion can enter in regard to proper nomenclature. A technicality of sorts, some companies cut corners in order to achieve zero-waste-to-landfill status by sending an inordinate amount of residual waste to an incinerator as a first-course action. Despite advances in waste-to-energy technology and methane capture, there are still concerns with the environmental impact of this practice.

Zero waste, meanwhile, is a classification that refers to the “conservation of all resources” through responsible and sustainable production, consumption, reuse, and recovery of products, packaging, and associated materials without incineration or environmental discharges.

That’s not to say the image of aspirational zero-waste-to-landfill commitments are tarnished, nor does it suggest that all corporate vows are “greenwashing,” the act of appealing to environmental concerns for brand perception gains.

There are countless companies executing zero-waste-to-landfill initiatives inextricable from their overall business objectives.

Companies That Have Committed to Zero Waste

According to a survey by Honeywell, 93% of companies see sustainability as a lasting priority, and 87% view it as a long-term investment instead of a cost.

More telling, 80% of companies have at least some form of sustainability initiative in place. However, unless businesses take an entire ecosystem approach to zero waste, the true cost- and planet-saving benefits likely won’t follow.

Below are some examples of organizations who have fully aligned their business with a zero-waste goal.

Subaru

Subaru became America's first zero-waste-to-landfill automaker, with 99.6% of their waste being recycled or reused. Over the last 15 years, their program has saved the company over $13 million. Subaru creates recovery and reduction plans for every form of waste generated in their Indiana-based plant. They design their products so they can easily be recycled or reused—from packaging materials to bumpers, airbags, and steel. And they even have two onsite composters to divert their organics from landfill.

PepsiCo

PepsiCo recently launched pep+, an end-to-end strategic decision said to be "the future of [its] company,” according to CEO Ramon Laguarta. In addition to extensive product packaging changes—like cutting the use of virgin plastic and increasing the use of recycled plastic—Pepsi has adhered to a stringent zero-waste-to-landfill practice. In 2020, the beverage company generated approximately 2.4 million metric tons of waste in manufacturing and warehouse operations, yet reportedly recycled ~2.3 million metric tons of it (98%).

Unilever

An early leader in sustainability, global CPG giant Unilever claimed its zero-waste-to-landfill certificate in 2016 (six years ahead of their initial goal!). Eliminating landfill waste across its operations at 600 sites in 70 countries, the company has succeeded by implementing and scaling a four-R framework across its products, byproducts, and operations: reduce, reuse, recover, and recycle.

Nestlé Waters

At Nestlé Waters’ North American plants, nearly all factory byproducts are reused, repurposed, or recycled. Of what isn’t—less than 5%—those materials are converted into an “alternative energy source.” Notably, as plastic is its biggest source of waste, the company has pledged to be more circular, with a goal to use 50% recycled plastic in products across its portfolio by 2025.

Not to be overlooked, results from Walmart, Google, Avery Dennison (a RoadRunner partner), Microsoft, Stanley Black & Decker, Whirlpool, Samsung, Procter & Gamble, as well as a number of spotlights from the EPA, provide a look into the ambitions and successes of sustainably minded companies.

Although, crafting a program from scratch or refining an existing initiative isn’t a cookie-cutter approach you can copy and see the same results. Any zero-waste initiative should start with proper planning.

How to Design A Zero-Waste Program

While many businesses balk at the idea of implementing programs on such large scales, even gradually easing into zero waste policies can start yielding big results.

As a partner in sustainability, RoadRunner works with companies to audit and streamline their waste services, driving year-over-year savings and improved efficiency. Based on our experience in helping implement these policies, we wanted to provide our SMB quick list to help your small or medium-sized business design a customized program that works.

1. Know Your Waste

Conduct a waste audit of your office, facility, factory, school, restaurant, etc. to identify types and volumes of waste generated in your business. Simplified, you’ll need to understand what types and how much per type your company produces on a regular basis in order to plan your approach for reduction. While waste audits can be completed informally, we recommend a more structured approach. If you need guidance on how it’s done, RoadRunner offers free, no-hassle consultations—just say the word.

2. Roundtable Discussion

A zero-waste-to-landfill strategy only works if a company is fully bought in. Invite multiple stakeholders from all aspects of your business to review common procedures, habits, and workflows to identify areas of excess and where you can cut waste. This conversation will help you set goals for your program and develop waste prevention and reduction strategies.

3. Nominate an Eco-Ambassador

Going back to the full-ecosystem approach, buy-in at the top can only go so far if it doesn’t trickle down. The success of your new program really depends on employee, student, guest, or faculty participation. Assign an "Eco" or "Green" Ambassador title to a motivated stakeholder who can act as the locus from which all program changes and motivations emerge. We provide more about the election process here.

4. Start with What You Can Control

While many companies are pursuing multi-scope reports detailing the sustainability of their partners and suppliers, they sure didn’t start there. Start with small changes unique to your own business. Here are a few easy ones that you can implement immediately: 1. Ensure your recycling program is efficient and widely understood. 2. Add material streams like food waste or mixed paper by communicating with your recycling partner. 3. Kick off discussions to redesign products and production methods for more natural and closed-loop processes.